DANIEL LAWSON

Tray Scanner

Disclaimer: This project was completed for Tesla Motors, Inc. While I was the primary designer, this system is now completely owned and operated by Tesla. I have been given permission to share the information below.

Goal: Design and build a fixture to prevent mislabeling of cell trays.

Background

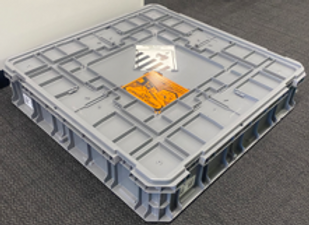

The cell trays shown below are used to transfer battery cells between different parts of the factory. Each tray has a unique barcode so that it can be tracked through production, which is labeled on each of the four sides of the tray. Each side is also labeled A through D to signify which face you are looking at. This is important because it allows for individual cells in the matrix to be referred to. Orienting the faces correctly ensures that one operator can call out a cell in Row 2 Column 3, and that same cell can be located by other operators even if the tray is moved.

It was discovered that multiple thousands of these trays were incorrectly labeled by the tray manufacturer.

For a tray to be properly labeled, it must:

-

Have a consistent barcode on each of the four labels

-

The face on the label must read A then B then C then D while spinning counter-clockwise

A

B

C

D

Cell Tray

Tray Barcodes

Brainstorm - Define features and scope components

I started defining the project parameters by deciding what was necessary and what would be nice to have.

Must Haves:

-

Check BCs are the same

-

Check BCs are in the correct order

-

Easier than manual inspection

-

Feasible for me to build

Nice to Have:

-

Record errors

-

Completely standalone

I started picking components with the barcode scanner. Tesla worked heavily with Keyence for their automation barcode scanning so I went with one of their scanners. I initially intended to use four scanners, one for each side, but that was much too expensive. Using just one scanner, I either had to make the tray move or the scanner, so I looked into turntables and sliding rails. For control, I looked into easy controllers like Arduinos or Raspberry Pi's as well as a basic PLC.

Keyence Scanners

Slide Rails

Turntable

PLC

Arduino

Design - Finalize components, develop code, CAD

I decided to use a turntable and move the tray rather than the scanner because the tolerances in the rails would make it difficult to get the scanner in the same place every time. I also chose to use a scanner with an integrated controller which saved me from having to use a PLC or Arduino. The language used to code the scanner controller was relatively simple and the Keyence team offered tons of support along the way. I designed the IO housing to be 3D printed and feature simple feedback. I did all modeling in SolidWorks and the components were all selected from McMaster-Carr.

Final CAD

Control Code

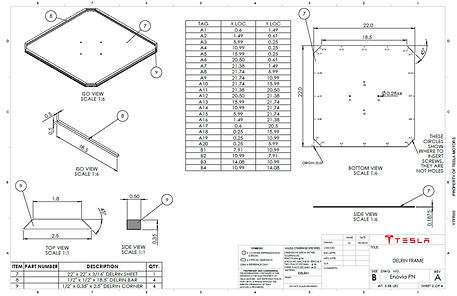

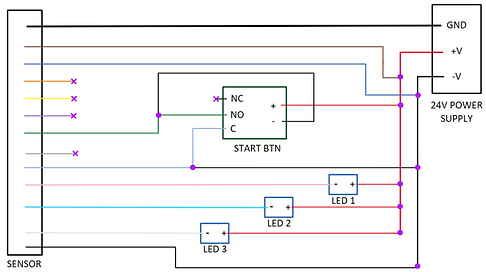

Because Tesla had internal fabrication, I did not need to do any of it by hand. Rather, I compiled all of the drawings, ordered the materials, and sent them off to get done by the fabrication team. While waiting for it to get back, I 3D printed the IO housing as well as designed the wiring schematic to include LEDs, a start button, and the sensor.

Fabrication Drawing

Wiring Schematic

Final Product

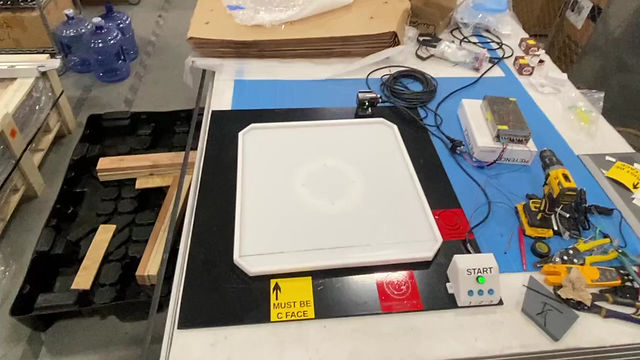

After receiving the machined parts, I did all assembly and wiring.

Empty Tray Scanner Fixture

Scanner Loaded with Tray

Future of the Fixture

As mentioned previously, it us up to the manufacturer to properly label the trays before sending them to Tesla. The prototype I created will either remain at Tesla to be used to test trays when a problem is found, or it will be sent to the manufacture to test all trays before shipping them out. It is more than likely this fixture will be replicated, perhaps incoroporating a data logging feature, to insure that the trays have been checked before shipping out.